In the world of industrial fabrication and metalworking, precision and efficiency are paramount. Plasma cutting technology has revolutionized the way we cut through conductive materials, offering speed, accuracy, and versatility. Among the latest advancements in this field are PlasmaSens, THC plasma cutters, and Mach3 plasma setups, each playing a crucial role in optimizing performance.

This article explores these three key innovations, with a special focus on PlasmaSens as a groundbreaking sensing technology. We’ll then delve into how THC plasma cutters enhance cutting accuracy and finally examine the role of Mach3 plasma setups in automating and streamlining plasma cutting operations. By the end, you’ll have a comprehensive understanding of how these technologies work together to push the boundaries of modern fabrication.

PlasmaSens – The Intelligent Sensing Revolution

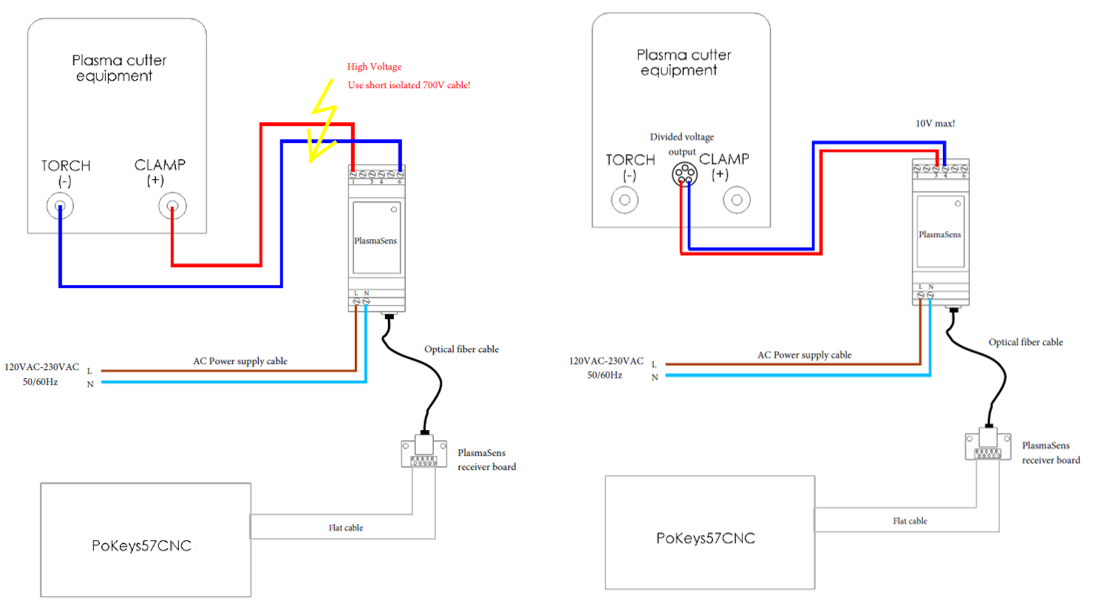

In the ever-evolving world of industrial plasma cutting, precision and adaptability are crucial. Enter PlasmaSens, a cutting-edge sensing technology designed to optimize plasma cutting operations by providing real-time feedback and adjustments. Unlike traditional systems that rely on manual calibration, PlasmaSens integrates intelligent sensors to monitor arc voltage, torch height, and material conditions, ensuring consistent cut quality even on uneven or warped surfaces.

How PlasmaSens Enhances Cutting Performance

At its core, PlasmaSens works by continuously analyzing the plasma arc’s electrical characteristics. If the torch drifts too far from the workpiece or encounters material inconsistencies, the system instantly compensates by adjusting the torch height. This dynamic response eliminates common issues like excessive dross, uneven cuts, or premature consumable wear.

For example, when cutting corrugated or rusted metal, traditional plasma systems may struggle to maintain an optimal standoff distance. PlasmaSens overcomes this challenge by detecting variations in the material surface and automatically fine-tuning the torch position. This not only improves cut quality but also extends the lifespan of consumables, reducing downtime and operational costs.

Key Benefits of PlasmaSens

Improved Cut Quality – By maintaining a consistent arc gap, PlasmaSens ensures smoother, more precise cuts with minimal kerf variation.

Reduced Manual Intervention – Operators no longer need to constantly adjust torch height, allowing for faster, more efficient production runs.

Enhanced Durability – Real-time adjustments prevent torch crashes and excessive wear, lowering maintenance requirements.

Versatility – Works seamlessly with various materials, including steel, aluminum, and stainless steel, even with surface imperfections.

Applications in Modern Fabrication

PlasmaSens is particularly valuable in industries where precision and speed are critical, such as automotive manufacturing, shipbuilding, and structural steel fabrication. Its ability to adapt to real-world cutting conditions makes it indispensable for high-mix, low-volume production environments where material consistency can vary.

As plasma cutting technology continues to advance, PlasmaSens stands out as a game-changer, bridging the gap between manual oversight and full automation. By integrating this intelligent sensing system, manufacturers can achieve unprecedented levels of efficiency and accuracy in their cutting processes.

THC Plasma Cutters – Precision Height Control for Flawless Cuts

While PlasmaSens provides the intelligence behind adaptive plasma cutting, THC plasma cutters (Torch Height Control systems) serve as the mechanical backbone that executes these precision adjustments. A THC plasma cutter is an essential component in modern CNC plasma tables, automatically maintaining the optimal distance between the torch and workpiece throughout the cutting process. This technology has become indispensable for achieving clean, consistent cuts in industrial applications.

How THC Plasma Cutters Work

A THC plasma cutter operates by continuously monitoring the voltage of the plasma arc. Since arc voltage correlates directly with the distance between the torch and material, the system can detect when the torch is too high or too low. When deviations occur, the THC plasma cutter instantly adjusts the torch height via servo motors or z-axis actuators, compensating for warped metal, slag buildup, or uneven surfaces.

For example, when cutting thick steel plates that may have slight warping, a manual plasma cutter would require constant operator intervention to prevent poor cut quality or torch damage. With a THC plasma cutter, the system automatically corrects the torch position, ensuring a steady arc length and minimizing defects like beveled edges or excessive dross.

Key Advantages of THC Plasma Cutters

Consistent Cut Quality – By maintaining the perfect arc gap, THC plasma cutters produce uniform cuts with smooth edges, reducing the need for secondary finishing.

Increased Productivity – Eliminates manual height adjustments, allowing for uninterrupted cutting even on imperfect materials.

Extended Consumable Life – Prevents torch crashes and reduces wear on nozzles and electrodes, lowering operational costs.

Better Piercing Performance – Automatically retracts during pierces to avoid splatter, then returns to the optimal cutting height.

Applications in Industry

THC plasma cutters are widely used in metal fabrication shops, automotive manufacturing, and heavy equipment production. They are particularly valuable when working with:

- Thick plate cutting (where warping is common)

- Intricate designs (requiring precise edge quality)

- High-speed production (where manual adjustments would slow workflow)

When paired with PlasmaSens technology, THC plasma cutters become even more effective, forming a closed-loop system that maximizes both precision and efficiency.

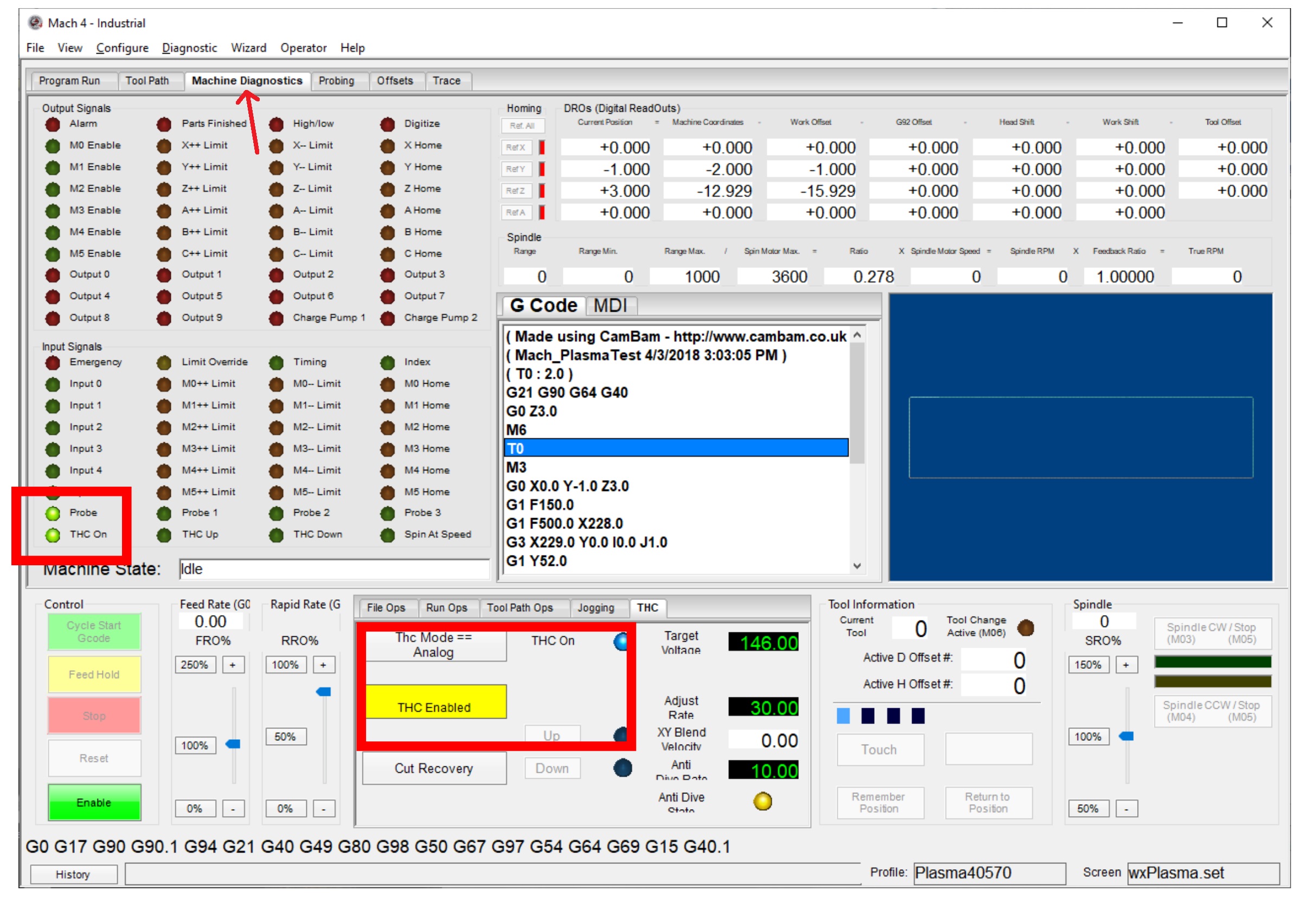

Mach3 Plasma Setup – The Brains Behind Automated Precision Cutting

While PlasmaSens provides intelligent sensing and THC plasma cutters deliver precise height control, the Mach3 plasma setup serves as the central nervous system that orchestrates the entire cutting operation. Mach3 is a powerful, PC-based CNC control software that transforms a standard plasma cutting table into a fully automated, high-precision fabrication system. When properly configured, a Mach3 plasma setup seamlessly integrates with both PlasmaSens and THC plasma cutters to deliver unmatched cutting performance.

Core Components of a Mach3 Plasma Setup

A complete Mach3 plasma setup consists of three key elements:

Mach3 Software – The control interface that interprets G-code and translates it into precise torch movements.

Motion Controller – Typically a breakout board that connects the computer to stepper/servo motors.

THC Interface – Allows Mach3 to communicate with the THC plasma cutter for real-time height adjustments.

When combined with PlasmaSens technology, the Mach3 plasma setup becomes even more responsive, using sensor data to make micro-adjustments during complex cuts.

Why Mach3 Dominates Plasma Cutting Automation

The Mach3 plasma setup remains popular among fabricators for several compelling reasons:

- Customizable Post-Processing – Easily adapts to different plasma cutter models and cutting requirements.

- Real-Time Monitoring – Provides visual feedback on cut progress and system diagnostics.

- THC Integration – Works flawlessly with most THC plasma cutters for automatic height control.

- Cost-Effective – More affordable than industrial CNC controllers while offering similar precision.

Optimizing a Mach3 Plasma Setup

To get the most from a Mach3 plasma setup, operators should:

Calibrate Axis Movements – Ensure steps-per-inch are perfectly tuned for accurate positioning.

Configure THC Settings – Adjust retract speeds and voltage thresholds for optimal performance.

Implement PlasmaSens Feedback – Fine-tune the system to respond to material variations.

Real-World Applications

From small metal art workshops to large-scale industrial fabrication, the Mach3 plasma setup provides the flexibility needed for diverse applications. Its ability to integrate with PlasmaSens and THC plasma cutters makes it particularly valuable for:

- Prototyping – Quickly test designs with precise, repeatable cuts.

- Production Runs – Maintain consistency across hundreds of identical parts.

- Complex Geometries – Execute intricate patterns that would be impossible manually.

When properly configured, a Mach3 plasma setup becomes the ultimate command center for plasma cutting – smart, adaptable, and relentlessly precise.

The Synergy of PlasmaSens, THC, and Mach3 – A Revolutionary Cutting Ecosystem

The individual strengths of PlasmaSens, THC plasma cutters, and Mach3 plasma setups pale in comparison to their combined potential. When these three technologies integrate seamlessly, they create an intelligent cutting ecosystem that redefines precision in metal fabrication. This chapter examines how their interconnection forms a system greater than the sum of its parts, delivering unprecedented performance in industrial plasma cutting.

At the heart of this integration lies a sophisticated feedback loop. PlasmaSens acts as the system’s sensory network, continuously monitoring arc characteristics and material conditions with microscopic precision. This real-time data flows into the Mach3 plasma setup, where advanced algorithms process the information and make instantaneous decisions. The Mach3 software then coordinates with the THC plasma cutter to execute perfect torch positioning adjustments, maintaining optimal cutting parameters throughout every operation.

The practical benefits of this integration manifest in several critical ways. First, the system achieves self-correcting precision that automatically compensates for material inconsistencies that would challenge conventional setups. Warped steel plates, variable material thickness, and even surface imperfections become non-issues as the trio of technologies works in concert to maintain perfect cutting conditions. Second, the combination enables intelligent process optimization that learns from each cutting operation, gradually refining its performance parameters for specific materials and applications.

A mid-sized fabrication shop recently documented remarkable improvements after implementing this integrated approach. Their production metrics showed a dramatic 15% increase in acceptable cut quality, while simultaneously reducing consumable costs by nearly half. Perhaps most impressively, their production rates jumped by 49%, demonstrating how the system’s automated precision translates directly into bottom-line results.

Despite its advanced capabilities, the integrated system does present some implementation challenges that require careful attention. Communication latency between components can sometimes create minor synchronization issues, often addressed through hardware upgrades or dedicated motion control cards. Sensor conflicts may occasionally arise, typically resolved through careful calibration of PlasmaSens detection thresholds and Mach3 response parameters. The system’s sensitivity can also lead to overcorrection in some cases, necessitating fine-tuning of the PID settings within the Mach3 plasma setup.

Looking ahead, this technological trifecta continues to evolve with exciting developments on the horizon. Artificial intelligence stands poised to take the system’s optimization capabilities even further, while wireless PlasmaSens monitoring and cloud-based Mach3 analytics promise to push the boundaries of remote operation and data-driven fabrication. What emerges is not just a collection of cutting technologies, but a truly intelligent manufacturing system that learns, adapts, and continuously improves its performance.

This integrated approach represents more than just an incremental improvement in plasma cutting – it constitutes a fundamental shift in how we approach precision metal fabrication. By harnessing the combined power of PlasmaSens sensory intelligence, THC’s mechanical precision, and Mach3’s computational control, manufacturers gain access to capabilities that were previously the domain of high-end industrial systems, now available at practical production scales.

The Future of Intelligent Plasma Cutting

The evolution of plasma cutting technology has reached a pivotal moment with the integration of PlasmaSens, THC plasma cutters, and Mach3 plasma setups. Together, these innovations form an intelligent cutting ecosystem that transcends traditional fabrication limitations, ushering in a new era of precision, efficiency, and automation in metalworking.

At the core of this transformation is PlasmaSens, whose sensory capabilities provide the system with unprecedented awareness of cutting conditions. This technology doesn’t just react to changes – it anticipates them, creating a proactive cutting environment that maintains quality even when working with imperfect materials. The THC plasma cutter serves as the perfect mechanical counterpart to this intelligence, executing micro-adjustments with robotic precision that human operators could never match.

The Mach3 plasma setup emerges as the crucial unifying element, transforming raw data into actionable commands and coordinating the entire cutting ballet. Its ability to learn and adapt turns what was once a static cutting process into a dynamic, evolving system that improves with each operation. The result is a manufacturing solution that doesn’t just perform tasks, but optimizes them in real-time.

Looking forward, the convergence of these technologies points toward an exciting future for metal fabrication. As artificial intelligence and machine learning become more sophisticated, we can expect these systems to develop predictive capabilities that further reduce waste and downtime. The integration of IoT connectivity will likely enable remote monitoring and adjustment, while advances in material science may allow for even more precise sensing and cutting of novel alloys.

For manufacturers and fabricators, this technological triad represents more than just upgraded equipment – it signifies a fundamental shift in production philosophy. The combination of PlasmaSens, THC plasma cutters, and Mach3 plasma setups doesn’t simply make cutting faster or more accurate; it creates a smarter, more responsive manufacturing environment where machines and materials communicate seamlessly. In doing so, it redefines what’s possible in metal fabrication, setting new standards for quality and efficiency that will shape the industry for years to come.